Precision Conveyors

80% fewer SKUs, lower costs and broader operating range.

Customer is a recognized leader in precision conveyors.

Conveyors move both large and small objects at relatively slow speeds, with frequent starts and stops. They require high torque to accelerate to full speed quickly and smoothly.

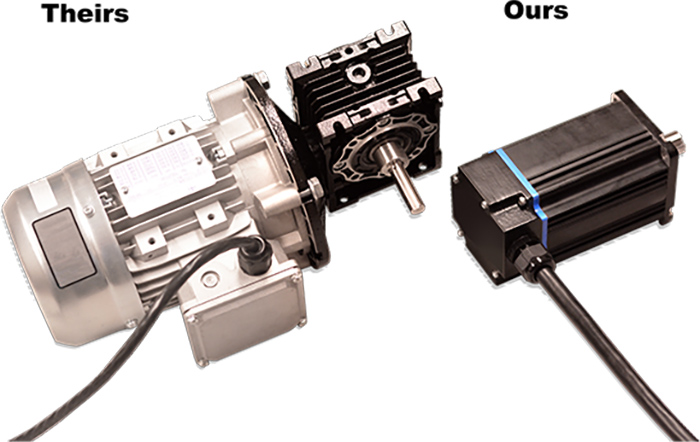

Incorporate a direct drive motor solution that reduces the overall drive system cost. Eliminate the need for the gearbox due to its poor reliability and lower efficiency, which have a negative impact on the customer experience.